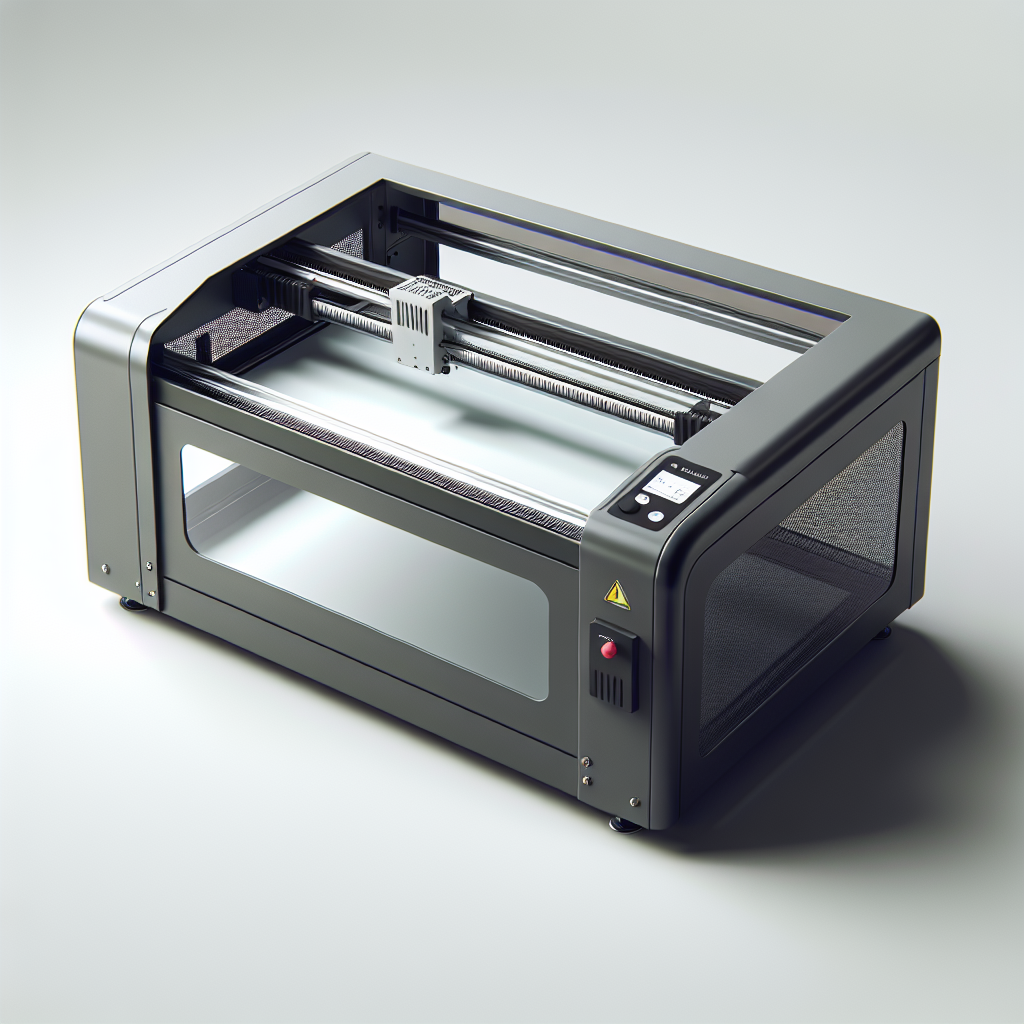

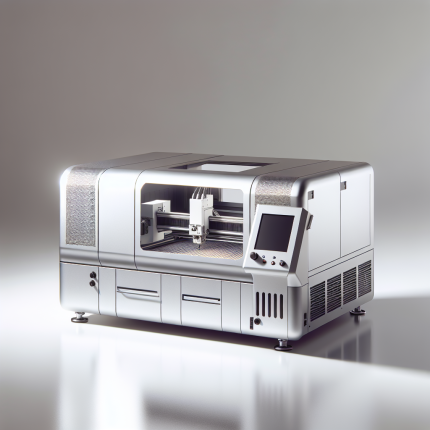

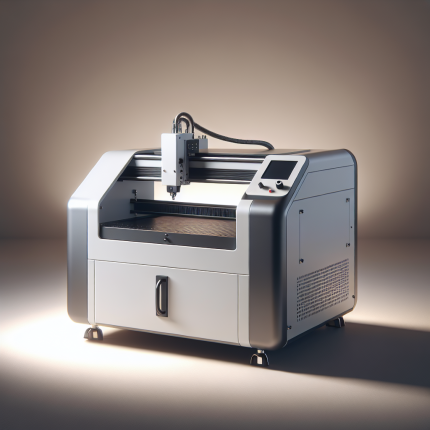

Transform your manufacturing or creative projects with our state-of-the-art laser acrylic cutter and laser engraving machines. Designed for precision, speed, and versatility, these systems deliver unmatched performance for industrial, commercial, and artistic applications. Whether you’re crafting intricate acrylic designs or engraving high-resolution logos, our machines combine cutting-edge technology with user-friendly operation.

- High-Power CO2 Laser Source

Equipped with a robust 60W–150W CO2 laser, our machines effortlessly cut through acrylic up to 25mm thick and engrave on wood, glass, leather, and metals (with specialized coatings). The adjustable power settings ensure optimal results for diverse materials. - Precision Motion Control

Achieve micron-level accuracy with industrial-grade linear guides and stepper motors. The 0.01mm repeat positioning guarantee ensures flawless consistency for batch processing and complex patterns. - Dynamic Dual Functionality

Seamlessly switch between laser acrylic cutting and engraving modes without recalibration. Integrated rotary attachment support enables cylindrical object processing for bottles, pens, and more. - Intuitive Software Integration

Compatible with CorelDraw, AutoCAD, and LightBurn, our machines feature real-time preview, layer-based editing, and parametric job queuing. USB 3.0 and Ethernet connectivity ensure rapid file transfers and network integration. - Enhanced Safety & Durability

Built with a fire-resistant stainless steel frame, air-assisted cooling, and emergency stop protocols. The enclosed workspace includes a smoke extraction port and safety interlocks for OSHA compliance.

Technical Specifications:

- Laser Type: CO2 RF Metal Tube

- Working Area: 600x900mm / 1200x1200mm (Customizable)

- Engraving Speed: 0–600mm/s

- Cutting Speed: 0–350mm/s

- Resolution: 4500 DPI

- File Compatibility: AI, DXF, BMP, PLT, SVG

Ideal for signage studios, aerospace prototyping, and personalized merchandise production, our laser engraving machines offer a scalable solution to meet evolving demands. Reduce material waste, minimize downtime, and elevate output quality with a system engineered for professionals, by professionals.

Benefits at a Glance:

Zero-contact processing preserves material integrity

Low maintenance with modular component design

Energy-efficient operation reduces overhead costs

Valentina Mueller (verified owner) –

The laser engraver excels in precision and versatility across materials like wood, acrylic, and leather. Engraving intricate designs on wood, such as detailed floral patterns, showcases its high-resolution capability without smudging. On acrylic, it achieves sharp cuts with minimal burn marks, ideal for signage. Setup was straightforward, requiring minimal adjustments. The software interface is user-friendly, though a steeper learning curve applies to advanced features. For artists and small businesses, this tool enhances productivity, though occasional minor maintenance is required to ensure optimal performance over time.

Ingrid Mitchell (verified owner) –

**As a Jewelry Designer: Experience with Laser Engraver**

**Specific Project Experience:**

I recently utilized the laser engraver on a stainless steel pendant project. The material behavior was consistent, allowing for intricate filigree patterns without melting or discoloration. The challenge was ensuring precision on delicate areas; adjusting the laser’s speed and power resolved this, yielding sharp, clean cuts.

**Technical Performance:**

The engraver operates effectively at 40W, providing sufficient power for metals. Its precision enables complex designs with minimal risk of material failure. The software is user-friendly, supporting CAD imports and offering modes tailored to metal engraving. Features like adjustable focal points and airflow control enhance efficiency and safety.

**Business/Creative Impact:**

This tool has streamlined my workflow, allowing faster creation of detailed pieces. Customer feedback highlights the exceptional craftsmanship, leading to increased orders. The ROI was evident within months due to higher productivity and customer demand.

**Comparison & Value:**

Compared to traditional tools like Dremels or hand engraving, the laser offers superior precision and speed. It’s cost-effective with reduced material waste and supports scalable production without compromising quality, making it a valuable asset for my studio.

Linda Lee –

“Exceptional laser engraver! Superb detail and precision, intuitive software, swift engraving speeds, and solid build quality. Highly reliable and a true workshop asset. 🌟🌟🌟🌟🌟”