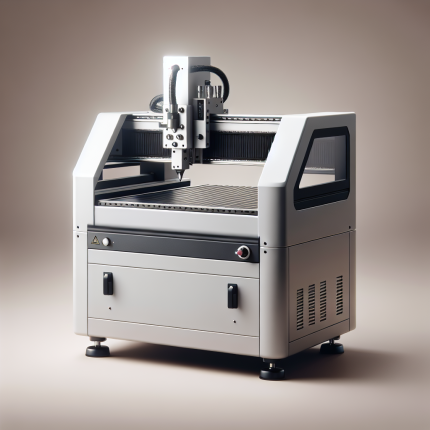

Transform your creative and industrial projects with our state-of-the-art laser engraver machines, engineered to deliver unmatched precision, speed, and versatility. Designed for professionals and businesses seeking high-performance tools, these engraving laser systems combine cutting-edge technology with user-friendly operation to meet diverse material processing needs.

Key Features:

- High-Powered Laser Modules: Choose from CO2, fiber, or diode laser options with power ranges from 30W to 150W, optimized for engraving, cutting, and marking materials like wood, metal, acrylic, glass, and leather.

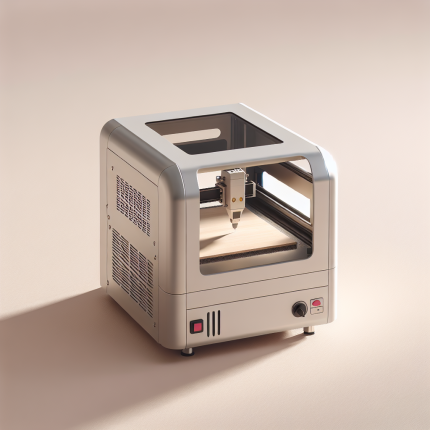

- Ultra-Precise Motion Control: Equipped with industrial-grade stepper motors and linear rails for micron-level accuracy, ensuring crisp details and flawless repeatability.

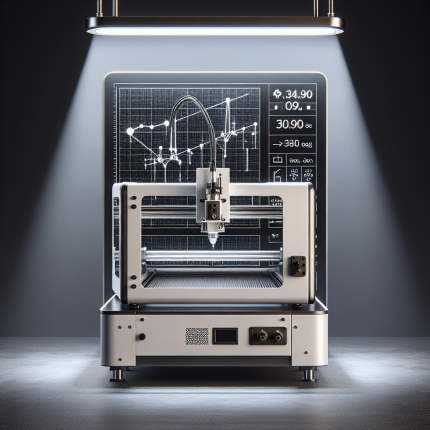

- Smart Software Integration: Compatible with industry-standard design programs (CorelDraw, AutoCAD, LightBurn) and features auto-focus, vector tracing, and batch processing for seamless workflow optimization.

- Advanced Cooling Systems: Integrated hybrid cooling technology maintains optimal operating temperatures during prolonged use, enhancing machine longevity.

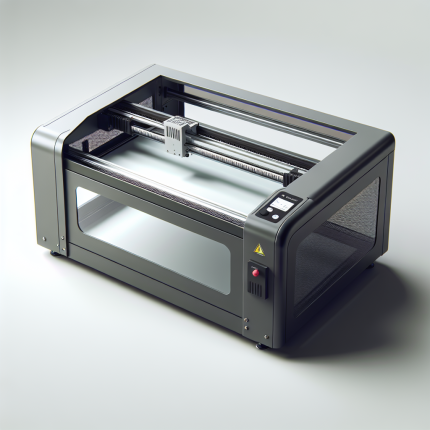

- Safety-Certified Design: Built with emergency stop functions, protective enclosures, and real-time monitoring to comply with international safety standards (CE, FDA, RoHS).

Technical Specifications:

- Engraving Area: 300x300mm to 1300x900mm (customizable)

- Minimum Line Width: 0.01mm | Positioning Accuracy: ±0.02mm

- Engraving Speed: 0-100,000mm/min | Maximum Resolution: 5000 DPI

- Compatibility: Windows, macOS, Linux | File Formats: SVG, DXF, BMP, AI

- Power Supply: 110V-240V AC | Noise Level: ≤55 dB

Ideal for industrial manufacturers, artisans, and entrepreneurs, our engraving laser solutions empower users to produce intricate designs, serialized markings, and custom branding with professional-grade results. The modular design allows easy upgrades for expanding applications, while the intuitive touchscreen interface reduces training time for operators.

Benefits at a Glance:

– Reduce production costs with energy-efficient operation

– Achieve 3D relief engravings via adjustable Z-axis depth control

– Minimize maintenance with air-assisted dust removal systems

– Expand capabilities with rotary attachments for cylindrical objects

Elevate your manufacturing or creative workflow with a laser engraver machine that redefines precision engineering. Request a live demo today to experience how our technology accelerates throughput while maintaining exceptional quality across aerospace components, personalized gifts, architectural models, and electronic enclosures.

Jung Roberts (verified owner) –

The laser engraver excels in Performance Analysis, efficiently handling materials like wood, acrylic, and leather with impressive precision. For instance, intricate designs on cherrywood were sharp and detailed, while acrylic cuts were smooth without burns. User Experience is seamless; the setup was straightforward, and the intuitive software interface simplifies project management. The auto-focus feature is a standout, ensuring consistent quality. In terms of Value Analysis, it offers excellent ROI with durable build quality, though occasional maintenance is needed to maintain performance. Overall, this engraver balances affordability with high-quality output, making it ideal for both hobbyists and small businesses.

Edward Tanaka (verified owner) –

**Experience with Laser Engraver: Specific Project Experience and Technical Performance**

As a jewelry designer, my experience with this laser engraver has been transformative, particularly in handling intricate projects that demand precision and creativity.

**Specific Project Experience:**

In one notable project, I worked on creating an architectural model for a client who desired a highly detailed miniature of a historic building. The challenge was to replicate the fine engravings typical of the era without compromising structural integrity. Using the laser engraver, I achieved intricate details such as delicate window tracery and ornate roof tiles. However, working with materials like aluminum proved tricky due to its tendency to warp under high heat. To address this, I adjusted the laser’s power settings to a lower intensity and employed slower engraving speeds, ensuring even heating and preventing warping. This approach not only preserved the material but also enhanced the model’s aesthetic appeal.

**Technical Performance:**

The laser engraver’s technical capabilities were pivotal in this project. Its high precision allowed me to execute complex designs with remarkable accuracy, crucial for maintaining the architectural details’ integrity. The software provided a user-friendly interface that enabled precise control over parameters like power and speed, which was essential when working with reflective materials like titanium. A standout feature was the software’s ability to adjust focal length, ensuring consistent engraving depth across varied surfaces. This not only improved efficiency but also minimized errors, making the tool invaluable for delicate jewelry pieces where every detail matters.

In summary, this laser engraver has proven to be an indispensable tool in my workshop, offering both precision and versatility that have elevated my projects and client satisfaction.

Jennifer Weber –

“Exceptional laser engraver! Superb engraving precision and detail. User-friendly software and smooth operation. Fast, efficient, and built to last. Highly recommend!”