The Ultimate Guide to Laser Cutters for Sheet Metal

Sheet metal fabrication has evolved significantly over the years, with modern technology offering innovative solutions for cutting, engraving, and shaping materials. Among these advancements, laser cutters have emerged as a game-changer, providing unparalleled precision and efficiency. If you’re exploring ways to enhance your sheet metal projects, understanding how laser cutters work and their benefits can be transformative. This article delves into everything you need to know about laser cutters for sheet metal, from their functionality to their applications.

What is a Laser Cutter for Sheet Metal?

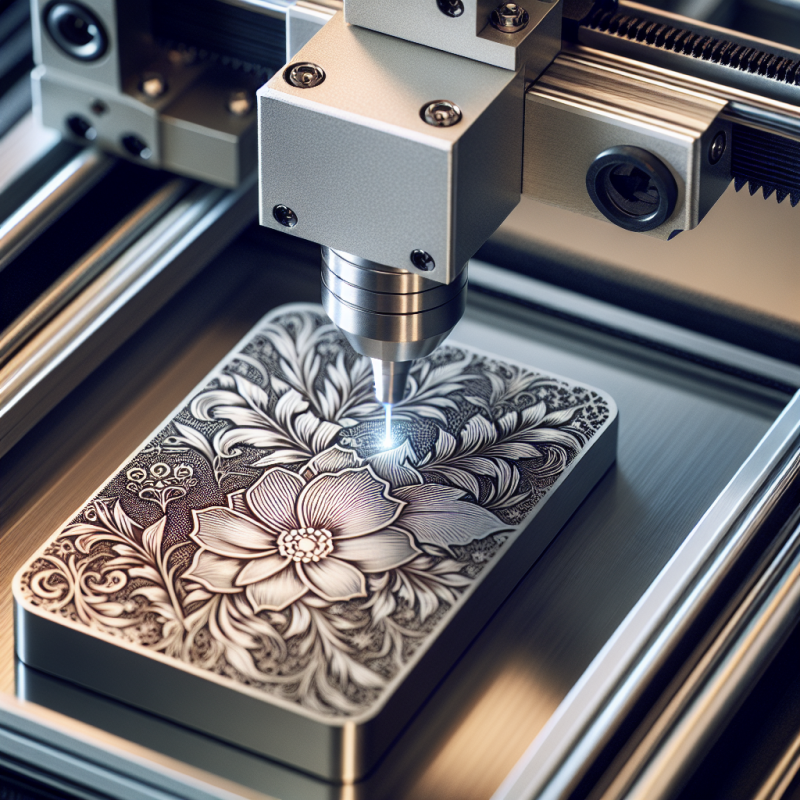

A laser cutter is a machine that uses a focused beam of light to cut, engrave, or etch materials with extreme precision. For sheet metal, these machines are designed to handle various thicknesses and types of metals, including stainless steel, aluminum, and mild steel. The process involves directing the laser beam at the material, which heats it to the point of vaporization or melting, creating clean and precise cuts.

The is particularly popular due to its ability to handle both thin and thick materials with ease. It’s ideal for industries ranging from automotive manufacturing to art and craft projects. Whether you’re creating intricate designs or cutting large sheets, this tool offers versatility and accuracy that traditional methods simply can’t match.

How Does a Laser Cutter Work?

The operation of a laser cutter is based on the principle of concentrating energy in the form of light. Here’s a simplified breakdown:

- The machine generates a high-power laser beam, typically using CO2 or fiber lasers.

- This beam is focused onto the surface of the sheet metal through mirrors and lenses.

- The intense heat from the laser causes the material to melt or vaporize at the point of contact.

- Air or gas assist systems are often used to blow away molten material, ensuring clean cuts.

Fiber lasers, in particular, are known for their efficiency and speed, making them a favorite among manufacturers. The machine’s software controls the laser’s path, allowing for complex designs and patterns to be cut with precision. This level of control ensures minimal waste and maximum productivity.

Advantages of Using a Laser Cutter for Sheet Metal

There are numerous benefits to using a laser cutter for sheet metal fabrication:

- Precision: Laser cutters produce clean, accurate cuts with minimal kerf (the width of the cut), ensuring that even intricate designs are executed flawlessly.

- Speed: Compared to traditional cutting methods, laser cutting is faster and more efficient, reducing production time significantly.

- Versatility: These machines can handle a wide range of materials, from thin gauge sheet metal to thick steel plates, making them suitable for diverse applications.

- Reduced Waste: The precision of laser cutting minimizes material waste, lowering costs and improving sustainability.

- Ease of Use: Modern laser cutters come with user-friendly software interfaces, allowing even those without extensive technical expertise to operate them effectively.

For industries that demand high-quality output, such as aerospace or electronics, the advantages of laser cutting are undeniable. The ability to produce precise and repeatable cuts ensures consistency in manufacturing processes.

Applications of Laser Cutters for Sheet Metal

The applications of laser cutters for sheet metal are vast and varied:

- Automotive Industry: Used to cut and shape components like body panels, brackets, and exhaust systems.

- Aerospace: Ideal for creating lightweight yet durable parts, such as engine components and frames.

- Construction: Fabricating structural elements like beams, trims, and decorative metalwork.

- Electronics: Cutting thin sheets of metal for circuit boards and enclosures.

- Art and Crafts: Creating custom designs, signage, and ornamental pieces with intricate details.

The versatility of laser cutters makes them a valuable tool in both industrial and creative settings. Whether you’re working on large-scale manufacturing or small-batch production, these machines deliver exceptional results.

Choosing the Right Laser Cutter for Your Needs

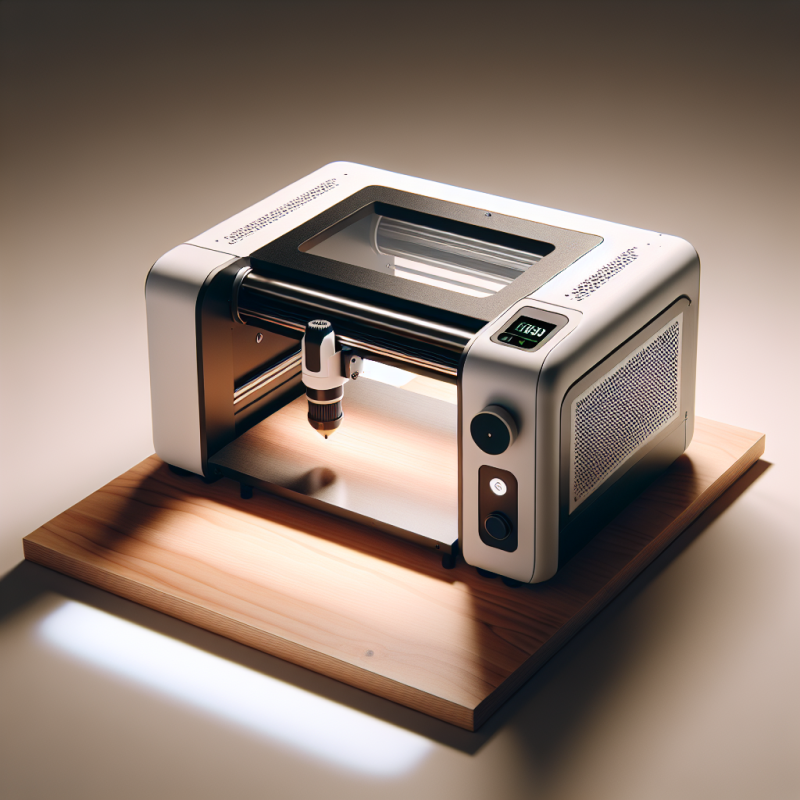

Selecting the right laser cutter for your sheet metal projects depends on several factors:

- Budget: Determine how much you’re willing to invest, as prices vary based on power output and features.

- Material Thickness: Consider the maximum thickness of sheet metal you’ll be cutting, as this affects the required laser power.

- Cutting Speed: Higher-powered lasers offer faster cutting speeds, which is crucial for large-scale production.

- Quality and Durability: Invest in machines with robust build quality to ensure long-term reliability.

- Additional Features: Look for features like air assist systems, adjustable focal length, and compatibility with CAD software.

Before making a purchase, it’s essential to evaluate your specific needs and choose a machine that aligns with them. For example, if you’re working on artistic projects, a lower-powered laser cutter might suffice, while industrial applications may require higher power output.

Maintenance and Safety Tips

Like any precision tool, a laser cutter requires proper maintenance to ensure optimal performance and longevity:

- Clean the Lenses: Regularly clean the focusing lenses to prevent dirt or debris from affecting cut quality.

- Check Gas Supply: Ensure that gas levels are adequate, as laser cutting relies on a steady supply of assist gas.

- Calibrate Regularly: Periodically check and adjust the machine’s alignment to maintain accuracy.

- Maintain Blade Sharpness: While not applicable to all machines, some laser cutters use mechanical blades that need sharpening or replacement over time.

Safety is also a top priority when operating a laser cutter. Always wear protective eyewear and follow manufacturer guidelines to minimize risks of injury or damage.

Frequently Asked Questions (FAQs)

Q1: Can laser cutters be used for cutting materials other than metal?

A: Yes, laser cutters can also cut plastics, wood, and glass, making them a versatile tool in various industries.

Q2: How much training is required to operate a laser cutter?

A: While some basic knowledge of CAD software is helpful, most modern laser cutters are designed for user-friendly operation, requiring minimal training.

Q3: What’s the difference between CO2 and fiber lasers?

A: Fiber lasers are more efficient, faster, and require less maintenance compared to traditional CO2 lasers. They’re also better suited for cutting reflective materials like stainless steel.

Q4: Can laser cutters handle thick sheet metal?

A: Yes, depending on the machine’s power output, some laser cutters can handle up to several inches of thick metal, making them suitable for heavy-duty applications.

Q5: Are laser cutters environmentally friendly?

A: Yes, due to their precision and reduced material waste, laser cutting is considered a more sustainable manufacturing method compared to traditional techniques.

Conclusion

Laser cutters have revolutionized the way sheet metal fabrication is approached, offering unparalleled precision, speed, and versatility. Whether you’re in the automotive industry, aerospace, or even crafting custom art pieces, these machines provide a reliable solution for diverse cutting needs.

If you’re considering investing in a laser cutter, it’s crucial to assess your specific requirements and choose a machine that aligns with your operational goals. With proper maintenance and safety practices, a laser cutter can be an invaluable asset for years to come.

Ultimately, the adoption of laser cutting technology not only enhances productivity but also contributes to more sustainable manufacturing processes. As industries continue to evolve, laser cutters remain at the forefront of innovation, enabling manufacturers to achieve higher standards of quality and efficiency.

Laser Cutters for Sheet Metal Fabrication: A Comprehensive Guide

In the dynamic world of manufacturing and craftsmanship, precision and efficiency are paramount. Laser cutters have emerged as a transformative tool in sheet metal fabrication, offering unparalleled accuracy and versatility across various industries.

Key Features of Laser Cutters

- Precision Cutting: Achieve clean, accurate cuts with minimal kerf, ideal for intricate designs.

- Speed and Efficiency: Fiber lasers, known for their rapid cutting speeds, significantly reduce production time compared to traditional methods.

- Versatility: Capable of handling diverse materials, from thin gauge sheet metal to thick steel plates, making them suitable for a wide range of applications.

Applications Across Industries

- Automotive Industry: Utilized for shaping body panels, brackets, and exhaust systems with precision.

- Aerospace Sector: Produces lightweight yet durable parts, essential for engine components and frames.

- Construction: Fabricates structural elements like beams and decorative metalwork efficiently.

- Electronics Manufacturing: Cuts thin sheets for circuit boards and enclosures with exactitude.

- Art and Crafts: Enables the creation of custom designs and ornamental pieces with intricate details.

Choosing the Right Laser Cutter

Considerations include budget, material thickness requirements, cutting speed needs, machine quality, and additional features like air assist systems. Evaluate your specific project demands to select a machine that optimally fits your operations.

Maintenance and Safety

- Lens Cleaning: Regularly clean focusing lenses to maintain cut quality.

- Gas Supply Check: Ensure adequate gas levels for efficient operation.

- Calibration: Periodically adjust alignment for accuracy.

- Safety Protocols: Wear protective eyewear and follow guidelines to minimize risks.

Frequently Asked Questions (FAQs)

- Q: Can laser cutters handle non-metal materials?

- A: Yes, they can cut plastics, wood, and glass, enhancing their versatility.

- Q: How much training is needed?

- A: Minimal, as modern machines are user-friendly with CAD software support.

- Q: Difference between CO2 and fiber lasers?

- A: Fiber lasers offer higher efficiency and speed, better for reflective materials.

- Q: Thickness capabilities?

- A: Some models handle several inches of thick metal, suitable for heavy-duty use.

- Q: Environmental impact?

- A: Laser cutting reduces waste, contributing to sustainable manufacturing practices.

Conclusion

Laser cutters are revolutionizing sheet metal fabrication with their precision and versatility. They enhance productivity and contribute to sustainable practices across industries. Investing in a laser cutter aligns with operational goals, offering long-term benefits with proper maintenance and safety measures. As industries evolve, laser cutting remains at the forefront of innovation, driving higher quality and efficiency standards.