The Ultimate Guide to Laser Metal Engraving Machine: Precision and Efficiency at Your Fingertips

Have you ever wondered how intricate designs are etched onto metals with such precision? The answer lies in the laser metal engraving machine, a revolutionary tool that has transformed industries by offering unparalleled accuracy and speed. Whether you’re an artist, a jeweler, or a manufacturer, this machine opens up endless possibilities for creating custom pieces with ease. Let’s delve into the world of laser engraving and discover how it can benefit your projects.

How Does a Laser Metal Engraving Machine Work?

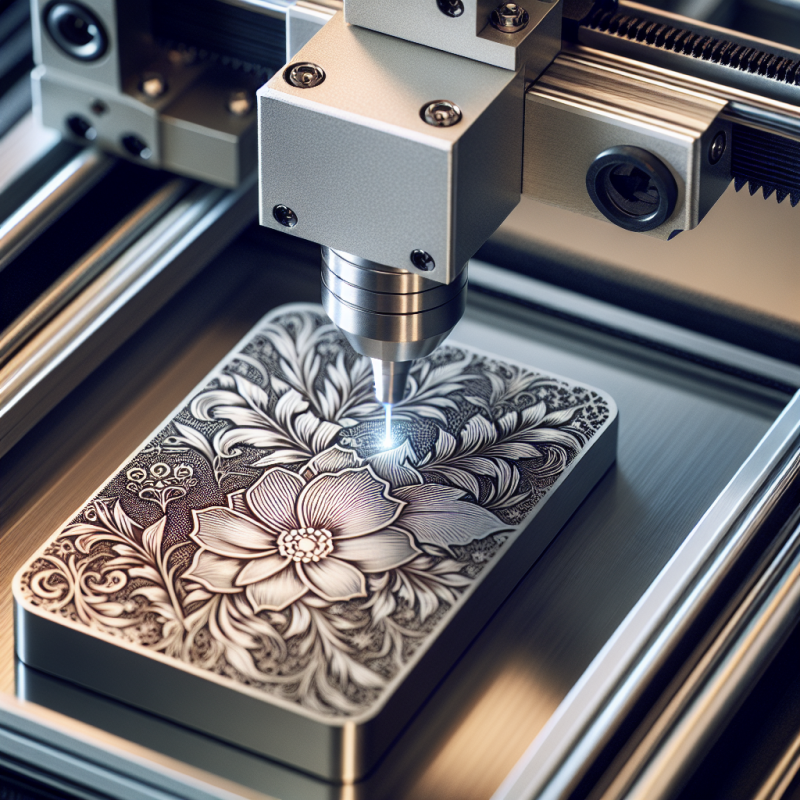

The laser metal engraving machine operates on a principle that combines high-powered lasers with advanced software to achieve precise engravings. Unlike traditional methods, which often require manual intervention and risk human error, this machine automates the process, ensuring consistency and quality every time. The laser beam focuses energy onto the metal surface, vaporizing or melting the material to create intricate designs. This method not only enhances precision but also significantly reduces production time.

One of the standout features is its ability to work with various materials, from stainless steel to titanium. But how does it handle different thicknesses and hardness levels? The machine’s advanced control systems allow for adjustments in laser power and speed, ensuring optimal results regardless of the material type. This flexibility makes it a versatile addition to any workshop or production line.

Key Benefits of Using a Laser Metal Engraving Machine

Incorporating a laser metal engraving machine into your workflow offers numerous advantages that can elevate your projects:

- High Precision: The laser beam’s pinpoint accuracy ensures even the most complex designs are reproduced faithfully.

- Versatility: Capable of engraving on various metals, it caters to a wide range of applications from jewelry making to industrial parts.

- Durability and Longevity: The engraved markings are permanent and resistant to wear, ensuring long-lasting quality.

- Energy Efficiency: Despite its power, the machine consumes minimal energy, contributing to cost savings over time.

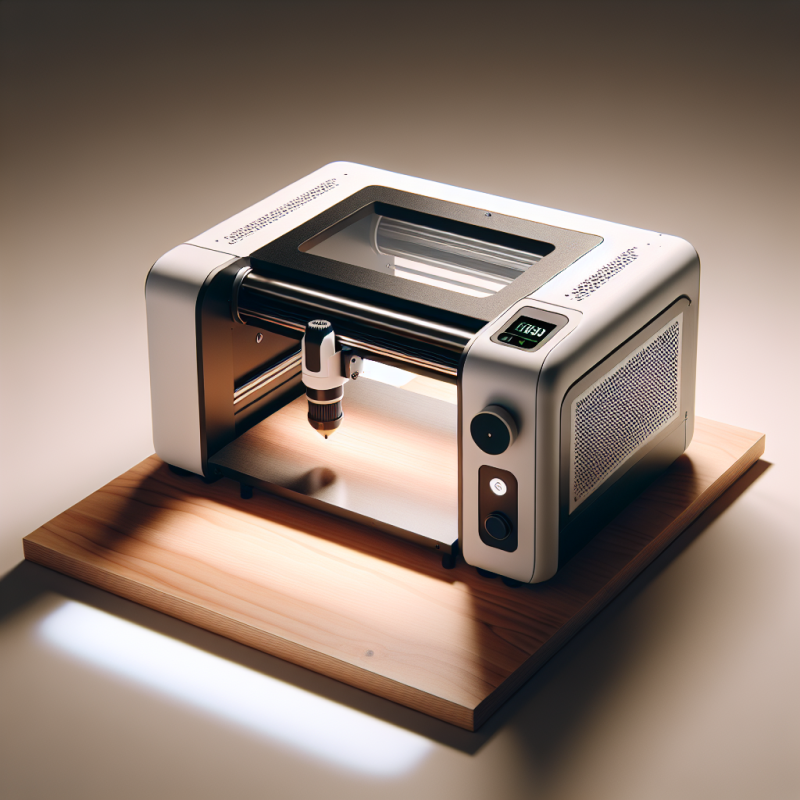

- Safety and Ease of Use: Equipped with safety features, it allows even those without extensive experience to operate with confidence.

Considering these benefits, it’s easy to see why the laser metal engraving machine has become a favorite among professionals. But what about its maintenance? Let’s explore that next.

Applications Across Industries

The applications of a laser metal engraving machine are vast and varied, making it an indispensable tool in multiple sectors:

- Jewelry Industry: Engravers can create intricate designs on rings, necklaces, and other precious metals with ease.

- Automotive Sector: Used for marking parts with serial numbers or logos, ensuring traceability and authenticity.

- Electronics Manufacturing: Ideal for engraving circuit boards and components with precise details.

- Medical Devices: Ensures that critical information is engraved accurately on surgical instruments and implants.

- Custom Products: Enables the creation of personalized items, such as engraved metal plaques or decorative pieces.

With its adaptability, this machine has found a home in numerous industries, driving innovation and efficiency. But how does it hold up over time? Proper maintenance is key to its longevity.

Tips for Maintaining Your Laser Metal Engraving Machine

To ensure your laser metal engraving machine continues to perform optimally, follow these care tips:

- Regular Cleaning: Keep the laser lens and surrounding areas free from dust and debris to maintain precision.

- Calibration Checks: Periodically check and adjust the machine’s settings to ensure accurate engraving.

- Firmware Updates: Stay updated with software patches to enhance performance and functionality.

- Proper Handling of Materials: Use appropriate clamps and fixtures to hold materials securely during engraving, preventing accidents.

By adhering to these maintenance practices, you can extend the machine’s lifespan and continue reaping its benefits for years to come. But what about when it comes time to invest in one? The decision is well worth it, given the transformative impact it can have on your projects.

Conclusion

In a world where precision and efficiency are paramount, the laser metal engraving machine stands out as an invaluable tool. Its ability to handle diverse materials with ease, combined with its high precision and versatility, makes it a must-have for any serious craftsperson or manufacturer. Whether you’re looking to start a new project or enhance your existing capabilities, this machine is sure to elevate your work to new heights.

Ready to take the plunge? Consider investing in a laser metal engraving machine today and unlock a world of creative possibilities. Visit our website to explore more details and discover how this innovative tool can transform your projects!